HOT WORK TOOL STEEL

-

H13

Hot work tools made of H13 material can be safely water cooled in hot work use where thermal shock cracking is not an issue. Its resistance to thermal fatigue, erosion, and wear makes it the mold material of choice for aluminum and magnesium die castings, as well as many other hot working applications. However, H13 metal is subject to hydrogen embrittlement and can be nitrided for additional wear resistance.

Email Details -

Hot

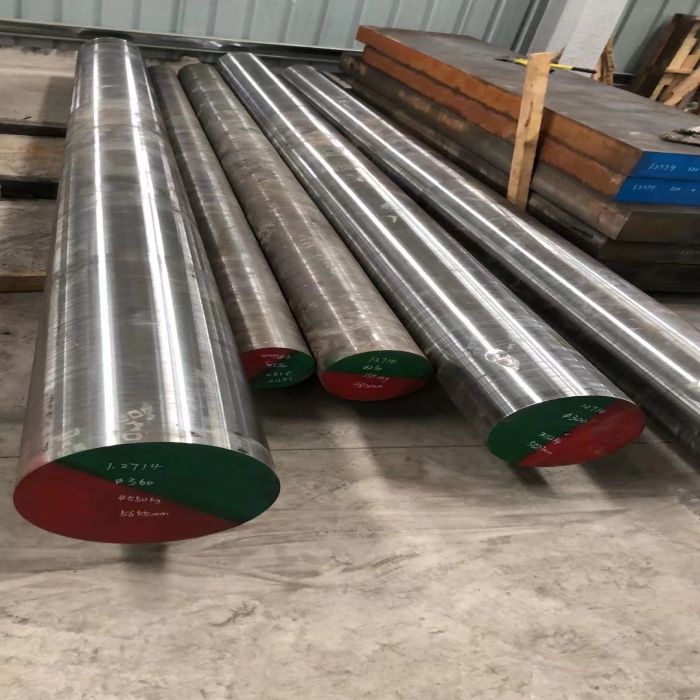

1.2714

55NiCrMoV7/1.2714 is an Ni alloyed die steel which has extreme toughness and good through hardening properties with very little size change after heat treatment.55NiCrMoV7/1.2714 is similar to AISI/SAE L6,and is used for making forging dies,hot shear knives,punches,backing plate,die holders,hot punching tools

Email Details -

Hot

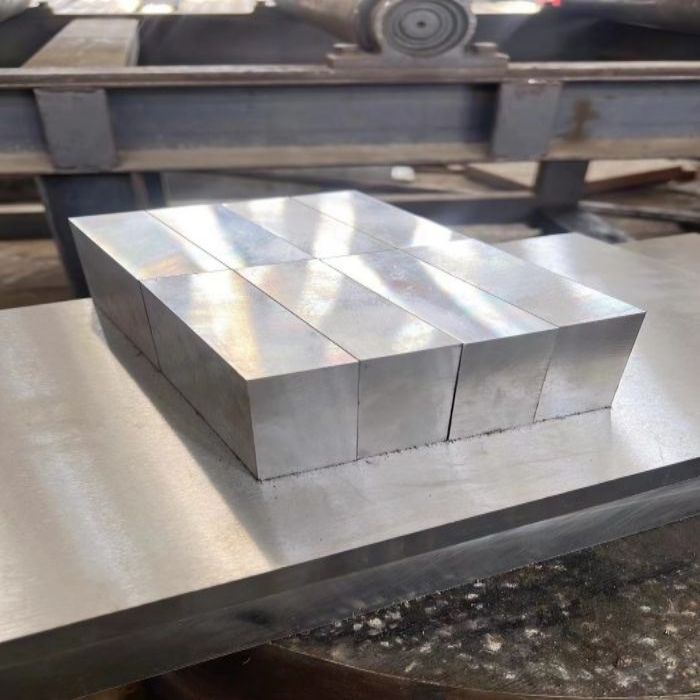

1.2344 precision machined block

1.2344 has good comprehensive performance at medium temperature (~600°), high hardenability (that can be hardened in the air), low heat treatment deformation rate, and its performance and service life are higher than 1.2581

Email Details

1.2344can be used for forging hammer forging dies, aluminum alloy die-casting dies, hot extrusion dies, high-speed precision forging dies and forging press dies, etc. -

Hot

1.2367 ESR bars

DIN 1.2367 ESR is a chromium-molybdenum-vanadium alloyed hot work tool steel with high

Email Details

thermal fatigue resistance. It has been refined via ESR process to ensure highest quality standards in terms of grain

size, segregation, micro-cleanliness, and purity. EN DIN 1.2367 features high isotropy, reason for which transversal

resilience is often three times higher when compared to conventional EN DIN 1.2367. Furthermore, the thermal

fatigue resistance is also often much higher than that of conventional hot work tool steel EN DIN 1.2343, enabling

longer die lifetime. -

1.2581 steel

Tungsten hot work tool steels are of different types, namely, H21 to H26 types. These hot work tool steel have similar characteristics to that of high speed tool steel. The primary alloying elements in tungsten hot work tool steel include tungsten, chromium, carbon, and vanadium. They are resistant to distortion when they are air hardened, and have higher hardening temperature when compared to chromium hot work tool steel. Breakage of the tungsten hot work tool steel can be reduced if they are preheated to operating temperature before use. Thermal shock resistance and toughness of these hot work tool steel can be improved by reducing the carbon content.

X30WCrV9 tool steel round and flat bar H21 tool steel round and flat bar SKD5 tool steel round and flat barEmail Details