TOOL STEEL

-

D2

D2 tool steel is a high carbon and high chromium-based grade that features excellent machinability and wear-resistance. This grade has maximum toughness at high hardness in sections of all sizes. In addition, D2 features a high level of resistance to abrasion due to a profusion of extremely hard wear-resisting alloy carbide particles that make up the steel.

Email Details -

H13

Hot work tools made of H13 material can be safely water cooled in hot work use where thermal shock cracking is not an issue. Its resistance to thermal fatigue, erosion, and wear makes it the mold material of choice for aluminum and magnesium die castings, as well as many other hot working applications. However, H13 metal is subject to hydrogen embrittlement and can be nitrided for additional wear resistance.

Email Details -

DC53

DC-53 is a general purpose, cold work die and mold steel that also provides excellent strength and toughness that approaches those of high-speed steels. DC53, is an improvement over alloy tool steel D-2. It eliminates the disadvantages of insufficient hardness and toughness that are a result of high-temperature tempering found with D-2. DC-53 is typically chosen as a replacement for D-2 in use for general purpose and precision dies. DC-53 is noted for causing less tool wear and machining times that are faster than D2 Tool Steel.

Email Details -

Hot

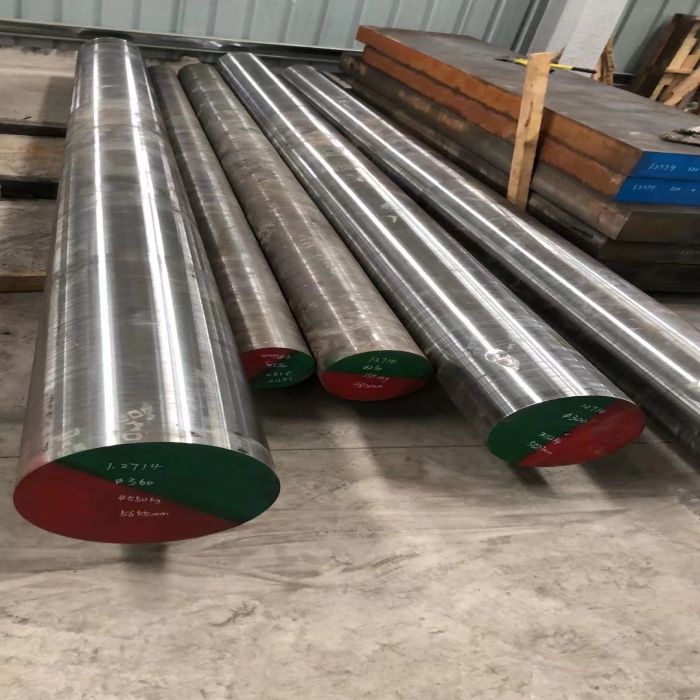

1.2714

55NiCrMoV7/1.2714 is an Ni alloyed die steel which has extreme toughness and good through hardening properties with very little size change after heat treatment.55NiCrMoV7/1.2714 is similar to AISI/SAE L6,and is used for making forging dies,hot shear knives,punches,backing plate,die holders,hot punching tools

Email Details