d2

-

D2

D2 tool steel is a high carbon and high chromium-based grade that features excellent machinability and wear-resistance. This grade has maximum toughness at high hardness in sections of all sizes. In addition, D2 features a high level of resistance to abrasion due to a profusion of extremely hard wear-resisting alloy carbide particles that make up the steel.

Email Details -

Hot

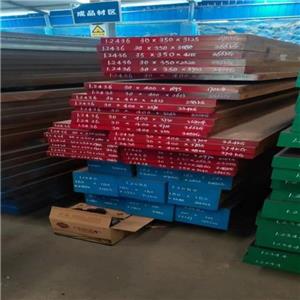

1.2379 machined flats

1.2379 is a tool steel with a carbon content of 1.5%, a chromium content of 11.5%, and a hardness of up to 60HRC after heat treatment. It is a kind of semi-stainless steel. D2 steel has good wear resistance and moderate toughness. The disadvantage is that the corrosion resistance is slightly insufficient. It is a kind of steel that is more suitable for practical use. Bob Dozier likes to use D-2. D2 steel is highly wear-resistant, slightly deformed cold work die steel, wind-hardened tool steel. D2 steel can be used to manufacture cold work die steels with large cross-sections, complex shapes, high impact resistance, and high wear resistance, such as silicon steel sheet die, cold cutting scissors, trimming die, etc.

Email Details -

Hot

SKD11 TOOL STEEL

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details

SKD11 steel is softened by spheroidizing annealing and has good machinability. The carbide particles are fine and uniform. There is no need to worry about the special addition of molybdenum and vanadium, which is the quenching cracking strengthening element.

SKD11 is produced by Hitachi and Datong Steel Plants. Hitachi’s SKD11 is produced under the trade name SLD (the latest improved version is called SLD-MAGIC), and Datong Steel Plant’s trade name is DC11. Both have factories in the mainland, and are the most well-known in the industry, and the prices are also the highest. The steel is a kind of air-cooled hardening cold work die steel widely used internationally. Smelted by electric furnace and remelted by electroslag, it has high purity, better toughness, uniform structure, good high temperature strength, toughness and high temperature fatigue resistance, and can withstand sudden temperature changes.

High hardness, high wear resistance eutectic carbide uniform, good toughness, not easy to crack, the hardness after quenching> 62HRC. The nitriding treatment time at 525℃ is 20h/30h/60h, the nitriding layer depth is 0.25mm/0.30mm/0.35mm, the surface hardness of the part is 1250HV; the nitriding treatment time at 570℃ is 2h, and the nitriding layer depth is 10~ 20μm, the surface hardness of the part is 950HV. -

1.2436 turned rounds

1.2436 high wear-resistant chromium steel, high carbon, high chromium ledeburite steel, cold work die steel.. Used to make cold work die with large cross-section, complex shape, high impact force and high wear resistance. Cold work molds include cold punching dies, wire drawing dies, drawing dies, stamping dies, thread rolling dies, thread rolling plates, cold heading dies and cold extrusion dies. The cold work die is made of steel, which should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability, hardenability and other process properties according to the working conditions of its manufacture. Alloy tool steels used for this kind of purposes generally belong to high-carbon alloy steels, with a carbon mass fraction above 0.80%. Chromium is an important alloying element of this type of steel, and its mass fraction is usually not more than 5%. However, for some steels with high wear resistance and small deformation after quenching, the highest chromium mass fraction can reach 13%, and in order to form a large amount of carbides, the carbon mass fraction in the steel is also very high, up to 2.0%~ 2.3%. Cold work die steel has a high carbon content, and most of its structure is hypereutectoid steel or ledeburite steel. Commonly used steels include high carbon low alloy steel, high carbon high chromium steel, chromium molybdenum steel, medium carbon chromium tungsten steel, etc.

Email Details