nc11lv

-

D2

D2 tool steel is a high carbon and high chromium-based grade that features excellent machinability and wear-resistance. This grade has maximum toughness at high hardness in sections of all sizes. In addition, D2 features a high level of resistance to abrasion due to a profusion of extremely hard wear-resisting alloy carbide particles that make up the steel.

Email Details -

Hot

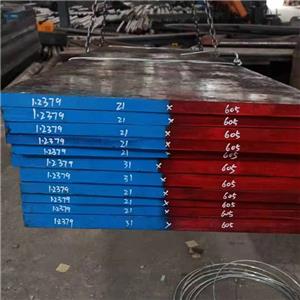

1.2379 machined flats

1.2379 is a tool steel with a carbon content of 1.5%, a chromium content of 11.5%, and a hardness of up to 60HRC after heat treatment. It is a kind of semi-stainless steel. D2 steel has good wear resistance and moderate toughness. The disadvantage is that the corrosion resistance is slightly insufficient. It is a kind of steel that is more suitable for practical use. Bob Dozier likes to use D-2. D2 steel is highly wear-resistant, slightly deformed cold work die steel, wind-hardened tool steel. D2 steel can be used to manufacture cold work die steels with large cross-sections, complex shapes, high impact resistance, and high wear resistance, such as silicon steel sheet die, cold cutting scissors, trimming die, etc.

Email Details -

SKD11 bright finish

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details