cr12w

-

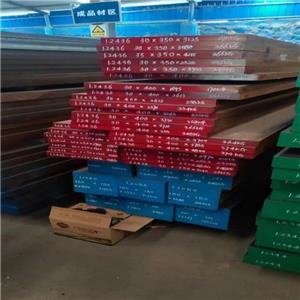

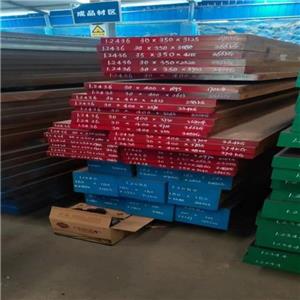

1.2436 turned rounds

1.2436 high wear-resistant chromium steel, high carbon, high chromium ledeburite steel, cold work die steel.. Used to make cold work die with large cross-section, complex shape, high impact force and high wear resistance. Cold work molds include cold punching dies, wire drawing dies, drawing dies, stamping dies, thread rolling dies, thread rolling plates, cold heading dies and cold extrusion dies. The cold work die is made of steel, which should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability, hardenability and other process properties according to the working conditions of its manufacture. Alloy tool steels used for this kind of purposes generally belong to high-carbon alloy steels, with a carbon mass fraction above 0.80%. Chromium is an important alloying element of this type of steel, and its mass fraction is usually not more than 5%. However, for some steels with high wear resistance and small deformation after quenching, the highest chromium mass fraction can reach 13%, and in order to form a large amount of carbides, the carbon mass fraction in the steel is also very high, up to 2.0%~ 2.3%. Cold work die steel has a high carbon content, and most of its structure is hypereutectoid steel or ledeburite steel. Commonly used steels include high carbon low alloy steel, high carbon high chromium steel, chromium molybdenum steel, medium carbon chromium tungsten steel, etc.

Email Details