TOOL STEEL

-

Hot

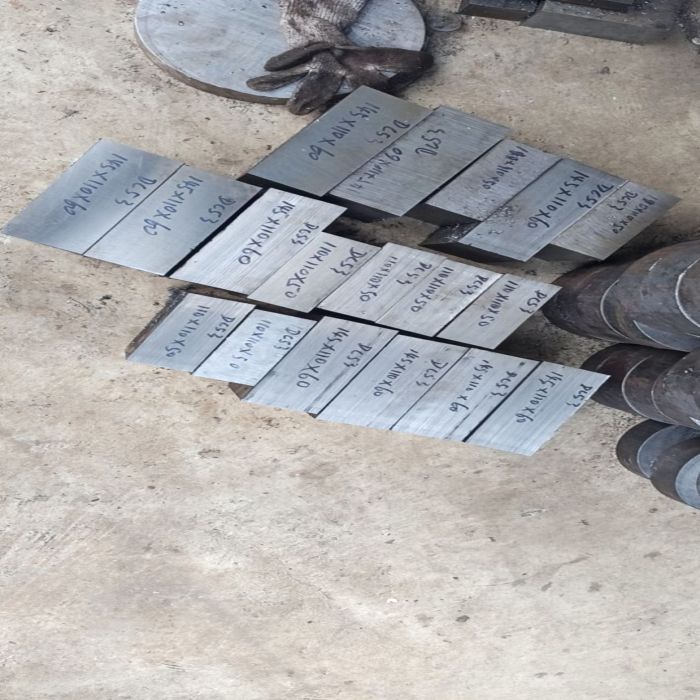

SKD11 TOOL STEEL

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details

SKD11 steel is softened by spheroidizing annealing and has good machinability. The carbide particles are fine and uniform. There is no need to worry about the special addition of molybdenum and vanadium, which is the quenching cracking strengthening element.

SKD11 is produced by Hitachi and Datong Steel Plants. Hitachi’s SKD11 is produced under the trade name SLD (the latest improved version is called SLD-MAGIC), and Datong Steel Plant’s trade name is DC11. Both have factories in the mainland, and are the most well-known in the industry, and the prices are also the highest. The steel is a kind of air-cooled hardening cold work die steel widely used internationally. Smelted by electric furnace and remelted by electroslag, it has high purity, better toughness, uniform structure, good high temperature strength, toughness and high temperature fatigue resistance, and can withstand sudden temperature changes.

High hardness, high wear resistance eutectic carbide uniform, good toughness, not easy to crack, the hardness after quenching> 62HRC. The nitriding treatment time at 525℃ is 20h/30h/60h, the nitriding layer depth is 0.25mm/0.30mm/0.35mm, the surface hardness of the part is 1250HV; the nitriding treatment time at 570℃ is 2h, and the nitriding layer depth is 10~ 20μm, the surface hardness of the part is 950HV. -

1.2581 steel

Tungsten hot work tool steels are of different types, namely, H21 to H26 types. These hot work tool steel have similar characteristics to that of high speed tool steel. The primary alloying elements in tungsten hot work tool steel include tungsten, chromium, carbon, and vanadium. They are resistant to distortion when they are air hardened, and have higher hardening temperature when compared to chromium hot work tool steel. Breakage of the tungsten hot work tool steel can be reduced if they are preheated to operating temperature before use. Thermal shock resistance and toughness of these hot work tool steel can be improved by reducing the carbon content.

X30WCrV9 tool steel round and flat bar H21 tool steel round and flat bar SKD5 tool steel round and flat barEmail Details -

1.2311 Mould Steel

1.2311 steel, German mold steel, the steel is produced through "ultra-pure" process, pre-hardened, showing a high degree of microscopic purity and excellent homogeneous structure, excellent polishing and photo-etching characteristics. After heat treatment, the processing and polishing performance is good, it can be nitrided, suitable for surface treatment such as chrome plating, the material has uniform hardness (up to 400mm thick), good toughness, and good mechanical processing performance. The gold structure is martensite and bainite.

Email Details -

Hot

1.2083 Mirror Steel

1.2083 mold steel is German Buderus special steel, plastic mold steel, the steel is high Cr stainless steel, with Cr content as high as 15%, has excellent wear resistance, acid resistance and good polishing performance, and good workability . After quenching, it is more wear-resistant, suitable for electro-erosion operation, suitable for acidic plastics and molds that require good polishing.

Email Details -

1.2343 cutting rounds

1.2343 die steel belongs to electroslag remelting hot-work die steel. It has uniform material and superior machinability and polishability, good high toughness and high plasticity, high wear resistance at high and low temperatures, and overall hardening performance.

Email Details -

Hot

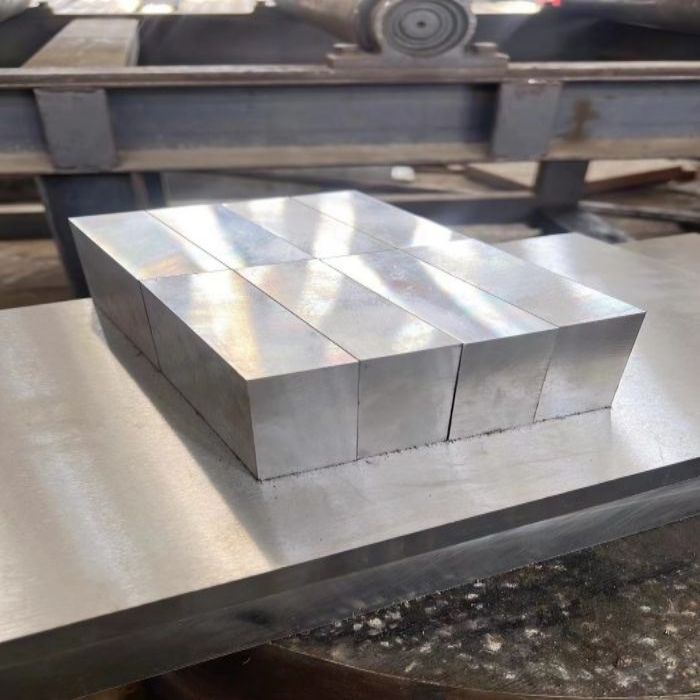

Hot forging die block 1.2714

1.2714 is Ni-Cr-Mo steel characterized by high level harden ability and toughness, good resistance to repeated shocks, fairly good insensitivity to thermal shocks and good wear resistance.

Email Details -

1.2316

Molds for pressing of chemically-aggressive plastic substances etc. all kinds of silicon steel sheet and high-speed blanking die. Precise stamping die. Cold extruding forming die. Cavitations Molds, Standard Mould Base, Compression Mould for SMC, blowing mould, Pet preform mold, plastic piping & plumbing injection molds.

Email Details -

Hot

DC53 STEEL

In the case of proper heat treatment, the strength and toughness are excellent, and the high temperature tempering hardness can reach 62~63HRC.

Email Details

The toughness of DC53 is more prominent in cold work die steel, and the tools made of DC53 rarely show cracks and cracks, which greatly improves the service life.

The residual stress after wire cutting is tempered at high temperature to reduce the residual stress. Therefore, cracks and deformation after online cutting of large molds and molds that require precision are suppressed. -

1.2510 tool steel

1.2510 steel German micro-deformation wear-resistant oil steel, this steel is manganese, chromium, tungsten alloy steel, high-quality non-deformation cold work tool steel. The steel is an excellent oil-quenched mold steel with good impact toughness, temper softening resistance, machining performance, toughness retention, high compressive strength, and small heat treatment deformation.

Email Details