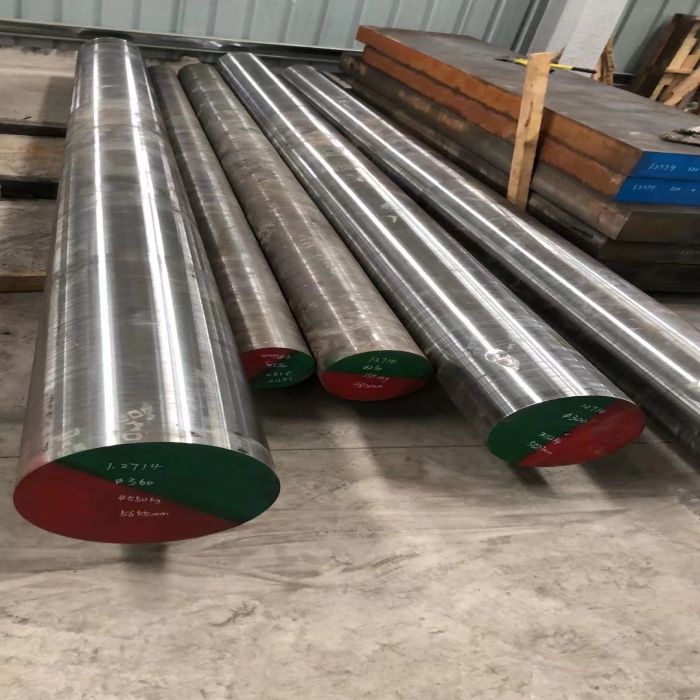

Hot forging die block 1.2714

- pinxin

- huangshi

- within 30-45days

- 500 Ton/Tons per Month

1.2714 is Ni-Cr-Mo steel characterized by high level harden ability and toughness, good resistance to repeated shocks, fairly good insensitivity to thermal shocks and good wear resistance.

1.2714 Chemical Analysis (%):

| C | Mn | Si | Cr | V | Mo | P | S |

| 0.50-0.60 | 0.65-0.95 | 0.10-0.40 | 1.00-1.20 | 0.07-0.12 | 0.45-0.55 | ≤0.03 | ≤0.03 |

1.2714 Heat treatment

Isothermal annealing:

- Heat to 800°Cand hold at temperature for 1/2 h to 1 h;

- Furnace cooling to 670°Cand hold at temperature for at least 10 hours;

- Cool by 10°C/h to 630°C;

- Cooling in air.

Maximum hardness:≤240 HB

Stress relieving:

To be carried out after maching before the final heat treatment.

- Heat to 600-650°C, hold for 4-6 hours;

- Cooling in furnace to 300-350°C;

- Cooling in air

Hardening:

- Initial preheating to 350-450°C;

- Second preheating to 650-750°C;

- Heat to hardening temperature 860-890°Cand hold at temperature;

- Cooling in hot oil (40-60°C); oil quenched hardness: 54-59HRC;

Tempering:

Tempering must be carried out within one hour from hardening(warm part) in the range 550-630°Cfor 4-6 hours according to hardness required, the dimensions of the parts and operating conditions.