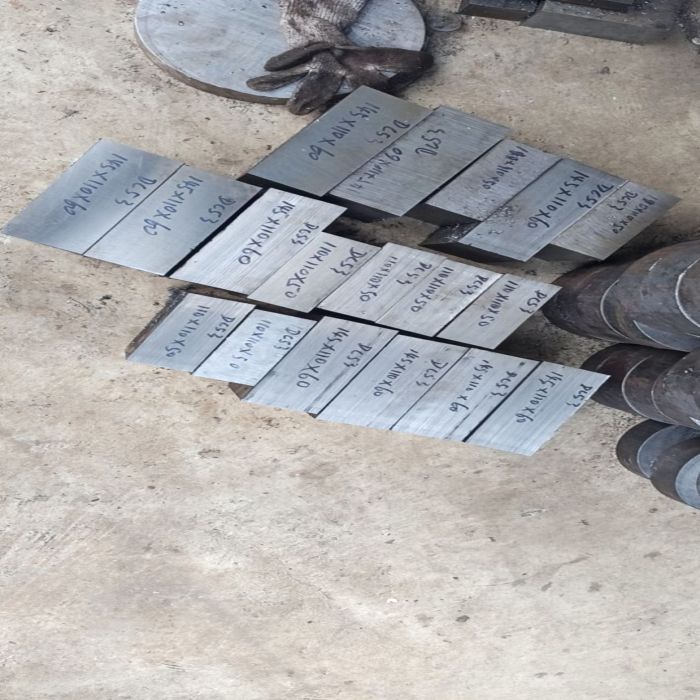

DC53 STEEL

- pinxin

- huangshi

- within 30-45days

- 5000ton/tons per month

In the case of proper heat treatment, the strength and toughness are excellent, and the high temperature tempering hardness can reach 62~63HRC.

The toughness of DC53 is more prominent in cold work die steel, and the tools made of DC53 rarely show cracks and cracks, which greatly improves the service life.

The residual stress after wire cutting is tempered at high temperature to reduce the residual stress. Therefore, cracks and deformation after online cutting of large molds and molds that require precision are suppressed.

Chemical composition % of steel DC53

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.90- 1.10 | 0.80- 1.20 | max 0.40 | max 0.03 | max 0.03 | 7.50- 8.50 | 1.80- 2.2 | 0.20- 0.50 |

The main purpose

1. Punching molds, cold forming molds, cold drawing molds

2. Forming rolls and punches

●Precision stamping die.

●Line cutting precision blanking die and various purpose stamping dies.

●Tools for plastic deformation of difficult-to-process materials.

●Dies for cold forging, deep drawing and thread rolling.

other

●High-speed blanking punches, stainless steel plate punches.

●Factory status: HB255

Product performance

Under DC53 conventional heat treatment conditions, the retained austenite is almost completely decomposed. Generally, cryogenic treatment can be omitted, and high toughness can still be maintained under strong hardness.

characteristic

1. Heat treatment hardness is higher than SKD11

After high temperature tempering, it can reach high hardness of 62-63HRC. In terms of strength and wear resistance, DC53 exceeds SKD11.

2. Toughness is twice that of SKD11

The toughness of DC53 is more prominent in cold work die steel, and the tools made of DC53 rarely show cracks and cracks, which greatly improves the service life.

3. The residual stress after wire cutting is small

After high temperature tempering, the residual stress is reduced, and the cracks and deformation after the wire cutting process are suppressed.

4. Machinability and abrasiveness exceed SKD11[1]

The machinability and abrasiveness of DC53 is better than that of SKD11. Using DC53 can increase tool and die life and reduce processing procedures.

Folding DC53 mold steel use

1. Precision stamping die

Precision blanking dies for wire cutting and stamping dies for various purposes.

2. Tools for plastic deformation of difficult-to-process materials

Die for cold forging, deep drawing and thread rolling.

3. Other

High-speed blanking punches, stainless steel plate punches.

Folding DC53 heat treatment

DC53 is a new type of cold work die steel improved from SKD11. Its technical specifications are contained in Japanese Industrial Standards (JIS) G4404. It overcomes the weakness of SKD11's insufficient high temperature tempering hardness and toughness, and will completely replace SKD11 in the field of general and precision molds.