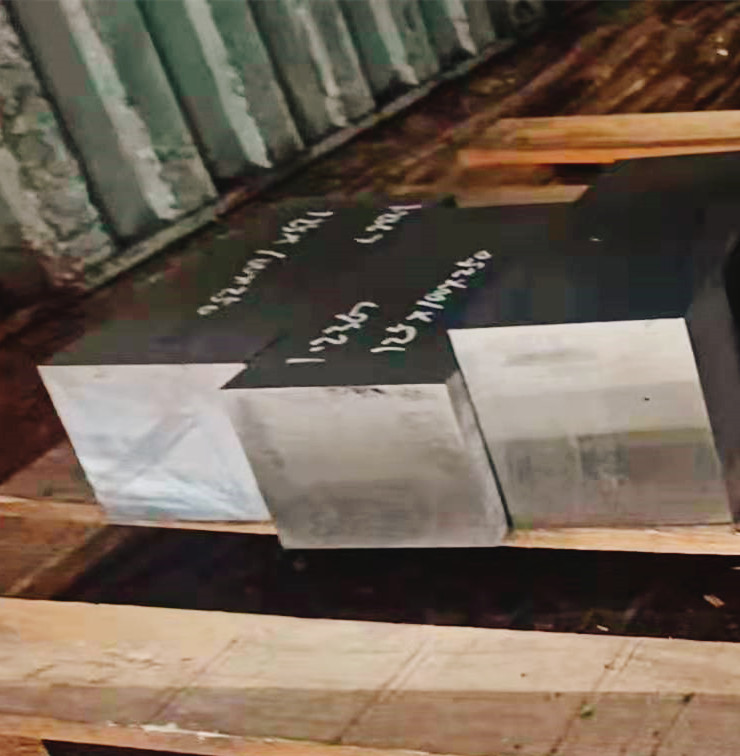

1.2311 Mould Steel

- pinxin

- huangshi

- within 25-30days

- 10000ton/tons per month

1.2311 steel, German mold steel, the steel is produced through "ultra-pure" process, pre-hardened, showing a high degree of microscopic purity and excellent homogeneous structure, excellent polishing and photo-etching characteristics. After heat treatment, the processing and polishing performance is good, it can be nitrided, suitable for surface treatment such as chrome plating, the material has uniform hardness (up to 400mm thick), good toughness, and good mechanical processing performance. The gold structure is martensite and bainite.

1.2311 steel Chemical Analysis (%):

| C | Mn | Si | Cr | Ni | Mo | P | S |

| 0.35-0.45 | 1.30-1.60 | 0.20-0.40 | 1.80-2.10 | - | 0.15-0.25 | ≤0.03 | ≤0.03 |

1.2311 State and hardness

Tempered and pre-hardened, hardness 285~325HBS.

Hot working specification

The initial forging temperature is 1050℃, the final forging temperature is 850℃, and it is slowly cooled with the furnace.

1.2311 Heat treatment method

Hard processing:

In order to increase the mold life to more than 800,000 mold times, the hardening method of quenching and low temperature tempering can be implemented on the pre-hardened steel. When quenching, preheat it at 500-600℃ for 2-4 hours, then keep it at 850-880℃ for a certain period of time (at least 2 hours), put it in oil and cool to 50-100℃ and air cooling, the hardness can reach 50 after quenching -52HRC, in order to prevent cracking, 200℃ low temperature tempering treatment should be carried out immediately. After tempering, the hardness can be maintained above 48HRC

1.2311 Nitriding treatment

Nitriding treatment can obtain high hardness surface structure, the surface hardness after nitriding reaches 650-700HV

(57-60HRC) The service life of the mold can reach more than 1 million times. The nitrided layer has the characteristics of dense and smooth structure, and the mold release performance and resistance to wet air and alkali corrosion are improved.

Softening annealing specification

Annealing temperature is 710~740℃, slow cooling in furnace, hardness ≤235HB.

Quenching and tempering specification

The quenching temperature is 840~870℃, oil cooling or 180~220℃ salt bath, the hardness after quenching is 51HRC, 1730MPa.

Tempering temperature is 100℃/200℃/300℃/400℃/500℃/600℃/700℃, hardness is 51HRC/50HRC/48HRC/46HRC/42HRC/36HRC/28HRC.

1.2311 Typical application examples

①Used for die-casting molds of zinc, aluminum, magnesium and their alloys

②Hot press dies, various hot forging dies

③Metal extrusion die base