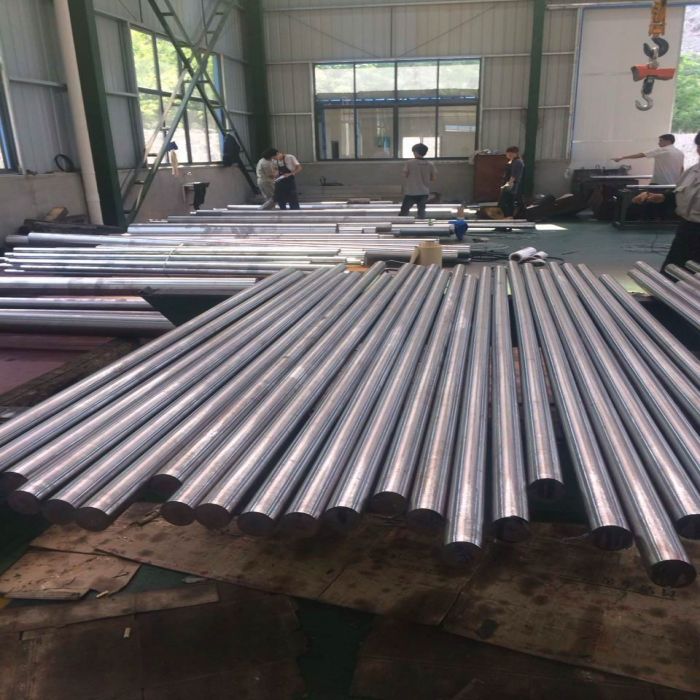

1.2080 tool steel

- pinxin

- Huangshi

- within 30-45days

- 5000 Ton/Tons per month

1.2080 die steel belongs to high carbon and high chromium ledeburite steel, and it is also a widely used cold work die steel. The steel has good hardenability, wear resistance, and hot workability. Carbides are well distributed in the steel and can be used It is used to manufacture various cold work molds with complex shapes and heavy working conditions, such as cold die punches, thread rolling dies, wire drawing dies, material molds, metallurgical powder molds, woodworking cutting tools, cold cutting scissors drill sleeves, gauges and other tools. In our research and development, after repeated exploration and testing, we have formulated a reasonable smelting process and a special ingot mold and forging process to achieve a uniform and consistent material structure. In addition, we have boldly innovated the standard material processing and adopted the new technology of double-knife chipping. The efficiency is greatly improved, the cycle is shortened, and the cost is reduced.

1.2080 steel Chemical Analysis (%):

| C | Mn | Si | Cr | V | Mo | P | S |

| 1.90-2.20 | 0.15-0.45 | 0.10-0.40 | 11.0-12.0 | - | - | ≤0.03 | ≤0.03 |

1.2080 steelFolding characteristics

1. Vacuum degassing and refining process the purity of steel.

2. Spheroidizing annealing softening treatment, good cutting performance.

3. The strengthening elements vanadium and molybdenum are specially added for excellent wear resistance.

1.2080 steel Folding use

1. Thin plates with a thickness of not more than 2MM, high-efficiency blanking die, punching die and stamping die.

2. All kinds of scissors, inlaid blades, woodworking blades.

3. Thread rolling die and wear-resistant slider.

4. Cold heading mold, thermosetting resin molding mold.

5. Stretch forming die, cold extrusion die.

Availability

hardness 269 -271HBW, indentation diameter 3.7-4.1mm

Corresponding grade

Chinese GB standard grade Cr12, German DIN standard material number 1.2080, German D1N standard grade x210Cr12, British BS standard grade BD3, French AFN0R standard grade z200Cr12, Italian UNI standard grade X210cr13KU/x250cr12I<U, Spanish UNE standard grade x210Cr12, Japanese Jis standard Grade SKD1, China Taiwan CNS standard grade 5KD1, South Korea KS standard grade sTD1, American Asm/UNS standard grade D3, 1T30403, International Organization for Standardization (IS0) standard grade 210cr12, Russian r0CT standard grade X12.

Folding mechanical properties

Hardness: Annealing, 269~271HB, indentation diameter 3.7~4.1mm; quenching, ≥58HRC

Folding heat treatment

Metallographic structure: tempered martensite + undissolved carbide + retained austenite.

Delivery status: The steel is delivered in an annealed state.