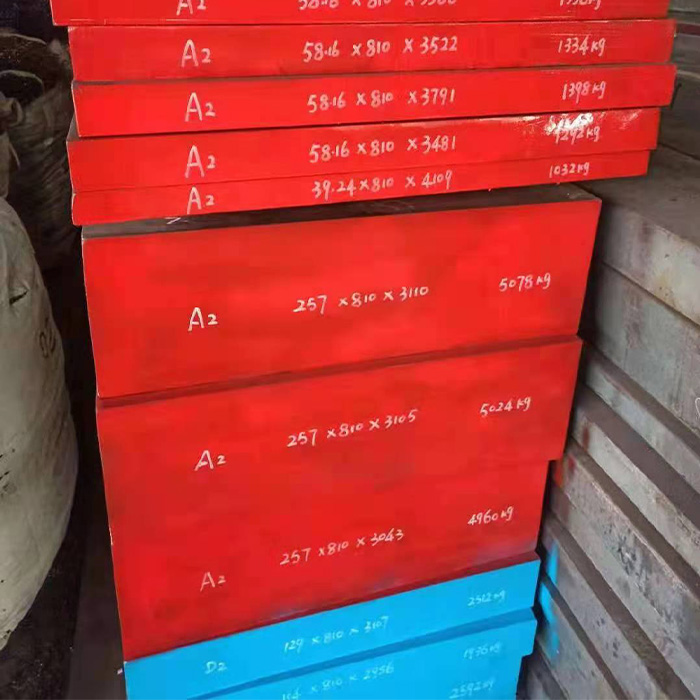

1.2363 cold work tool steel

- pinxin

- huangshi

- within 30-45days

- 5000ton/tons per month

A2 steel is an air-quenched die steel with deep air-quenched hardening properties, which is extremely beneficial for complex molds that must maintain their shape after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. The wear resistance is between manganese and high-carbon and high-chromium tool steels. Its toughness is better than any one, especially It is suitable for tools that require good wear resistance and special toughness. It is widely used in blanking dies and forming dies, rolls, punches, calendering dies and thread rolling dies, and also used in some types of scissors blades. . Cold work die steel is A2 steel imported from the United States, and it is the most widely used type of A-type air-quenched steel. It is suitable for cold work die steel that requires both wear resistance and toughness. It can replace CrWMn and 9Mn2V steel to make medium and small cold blanking dies, blanking dies, forming dies and punches.

Chemical composition % of steel A2

C | Si | Mn | P | S | Cr | Mo | V |

0.95 - 1.05 | 0.1 - 0.4 | 0.4 - 0.8 | max 0.03 | max 0.03 | 4.8 - 5.5 | 0.9 - 1.2 | 0.15 - 0.35 |

A2 is a high-carbon, medium-chromium, micro-deformed air-quenched die steel and alloy tool steel. The steel has a medium alloy content. Because it contains molybdenum and vanadium, it has good air-quenching performance, small air-quenching size deformation, uniform carbide distribution, a certain impact toughness and relatively good wear resistance.

The steel has good hardenability, which is extremely beneficial for complex molds that must maintain their shape after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese oil-quenched tool steels, and its resistance is between manganese and high-carbon high-chromium tool steels. Its toughness is excellent, and it is better than O2 and D3. .

The spheroidizing annealing temperature of the steel is 820 ~ 860℃; the quenching temperature should not exceed 950°C while ensuring that more carbon and alloying elements are dissolved in the austenite; the quenching cooling method should be oil cooling.

Reference corresponding grade

Chinese GB standard grade Cr5Mo1V, Japanese standard grade SKD12, Swedish ASSAB (ASSAB) standard grade XW-10, China Taiwan CNS standard grade SKD12, South Korea KS standard grade STD12, American ASTM/UNS standard grade A2/T30102, International Organization for Standardization (ISO) Standard grade 100CrMoV, German DIN standard grade X100CrMoV5-1, Dewei DIN standard material number 1.2363, French NF standard grade X100CrMoV5, Sweden SS standard grade 2260, British BS standard grade BA2.

Collapse edit the purpose of this paragraph

It is suitable for various hardware cold punching dies, as well as large and complex punching dies that can withstand greater impact.

Features

1. Air-quenching die steel has deep air-quenching hardening performance,

2. High wear resistance, slight deformation, high hardenability, high compressive strength,

3. The carbide distribution is more even than that of D3 steel.

Heat treatment

Annealing: 1, 800-850oC slow cooling 2, spheroidizing annealing process

Tempering: 180-220oC air cooling HRc=60-64 510-520oC air cooling HRc=57-60

Typical application examples

1) It is used to form elastic steel plates with a carbon content of 0.65% to 0.80%, with a hardness of 37 to 42HRC, and a service life of 110,000 to 120,000 times.

2) It is used for forming elastic steel plates with a carbon mass fraction of 0.65% ~ 0.80%, with a hardness of 37 ~ 42HRC, plus nitriding treatment, and the service life can reach 400,000 times.

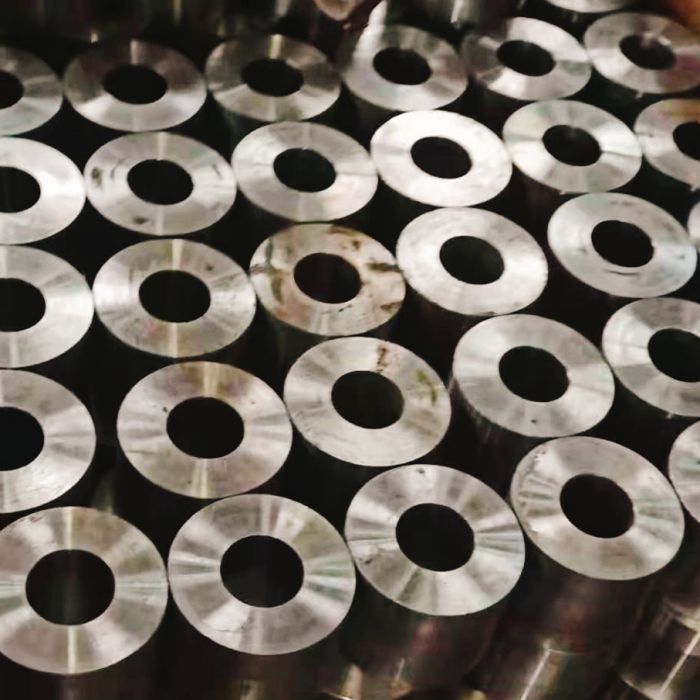

3)1 This steel is used for thread rolling die and can be used for processing aluminum alloy and copper alloy.

4) Suitable for making tough, wear-resistant forming dies, blanking dies, cold blanking dies, etc.

5) l It is suitable for tools that require good wear resistance and special toughness at the same time.

6) Widely used in blanking die and forming die, roll, drawing die.

7) Used for some types of cutting tools.

8) Used to make drill sleeves, punches, trimming dies and thread rolling dies, etc.

9) For wear-resistant plastic molds, etc.