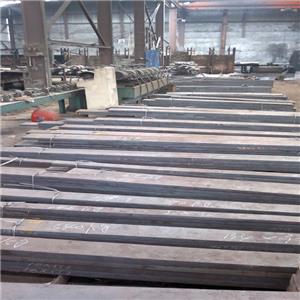

die steel

-

Hot

SKD11 TOOL STEEL

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details

SKD11 steel is softened by spheroidizing annealing and has good machinability. The carbide particles are fine and uniform. There is no need to worry about the special addition of molybdenum and vanadium, which is the quenching cracking strengthening element.

SKD11 is produced by Hitachi and Datong Steel Plants. Hitachi’s SKD11 is produced under the trade name SLD (the latest improved version is called SLD-MAGIC), and Datong Steel Plant’s trade name is DC11. Both have factories in the mainland, and are the most well-known in the industry, and the prices are also the highest. The steel is a kind of air-cooled hardening cold work die steel widely used internationally. Smelted by electric furnace and remelted by electroslag, it has high purity, better toughness, uniform structure, good high temperature strength, toughness and high temperature fatigue resistance, and can withstand sudden temperature changes.

High hardness, high wear resistance eutectic carbide uniform, good toughness, not easy to crack, the hardness after quenching> 62HRC. The nitriding treatment time at 525℃ is 20h/30h/60h, the nitriding layer depth is 0.25mm/0.30mm/0.35mm, the surface hardness of the part is 1250HV; the nitriding treatment time at 570℃ is 2h, and the nitriding layer depth is 10~ 20μm, the surface hardness of the part is 950HV. -

Hot

Hot forging die block 1.2714

1.2714 is Ni-Cr-Mo steel characterized by high level harden ability and toughness, good resistance to repeated shocks, fairly good insensitivity to thermal shocks and good wear resistance.

Email Details -

1.2363 cold work tool steel

A2 steel is an air-quenched die steel with deep air-quenched hardening properties, which is extremely beneficial for complex molds that must maintain their shape after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. The wear resistance is between manganese and high-carbon and high-chromium tool steels. Its toughness is better than any one, especially It is suitable for tools that require good wear resistance and special toughness. It is widely used in blanking dies and forming dies, rolls, punches, calendering dies and thread rolling dies, and also used in some types of scissors blades. . Cold work die steel is A2 steel imported from the United States, and it is the most widely used type of A-type air-quenched steel. It is suitable for cold work die steel that requires both wear resistance and toughness. It can replace CrWMn and 9Mn2V steel to make medium and small cold blanking dies, blanking dies, forming dies and punches.

Email Details -

1.2842 blade steel

1.2842 steel is cold work die steel is easy to forge and requires a hardness of 63HRC.

Email Details

chemical composition

1.2842 chemical composition (mass fraction): C0.85% ~0.95%, Si0.10% ~0.40%, Mn1.90%~2.10%, P≤0.030%, S≤0.030%, Cr0.20% -0.50% , V0.05% ~0.15%.

Reference corresponding grade

Chinese GB standard grade 9Mn2V, international standard ISO grade 90MnV2, German DIN standard grade 90MnV8, German DIN standard material number 1.2842, American ASTM standard grade 02, British BS standard grade B02, Sweden ASSAB (ASSAB) standard grade DF- 20 -

1.2365 milled block

1.2365 die steel is used to manufacture forging dies with high impact load, hot extrusion dies, precision forging dies; die-casting dies for aluminum, copper and their alloys.

Email Details