COLD WORK TOOL STEEL

-

Hot

SKD11 TOOL STEEL

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details

SKD11 steel is softened by spheroidizing annealing and has good machinability. The carbide particles are fine and uniform. There is no need to worry about the special addition of molybdenum and vanadium, which is the quenching cracking strengthening element.

SKD11 is produced by Hitachi and Datong Steel Plants. Hitachi’s SKD11 is produced under the trade name SLD (the latest improved version is called SLD-MAGIC), and Datong Steel Plant’s trade name is DC11. Both have factories in the mainland, and are the most well-known in the industry, and the prices are also the highest. The steel is a kind of air-cooled hardening cold work die steel widely used internationally. Smelted by electric furnace and remelted by electroslag, it has high purity, better toughness, uniform structure, good high temperature strength, toughness and high temperature fatigue resistance, and can withstand sudden temperature changes.

High hardness, high wear resistance eutectic carbide uniform, good toughness, not easy to crack, the hardness after quenching> 62HRC. The nitriding treatment time at 525℃ is 20h/30h/60h, the nitriding layer depth is 0.25mm/0.30mm/0.35mm, the surface hardness of the part is 1250HV; the nitriding treatment time at 570℃ is 2h, and the nitriding layer depth is 10~ 20μm, the surface hardness of the part is 950HV. -

Hot

DC53 STEEL

In the case of proper heat treatment, the strength and toughness are excellent, and the high temperature tempering hardness can reach 62~63HRC.

Email Details

The toughness of DC53 is more prominent in cold work die steel, and the tools made of DC53 rarely show cracks and cracks, which greatly improves the service life.

The residual stress after wire cutting is tempered at high temperature to reduce the residual stress. Therefore, cracks and deformation after online cutting of large molds and molds that require precision are suppressed. -

1.2510 tool steel

1.2510 steel German micro-deformation wear-resistant oil steel, this steel is manganese, chromium, tungsten alloy steel, high-quality non-deformation cold work tool steel. The steel is an excellent oil-quenched mold steel with good impact toughness, temper softening resistance, machining performance, toughness retention, high compressive strength, and small heat treatment deformation.

Email Details -

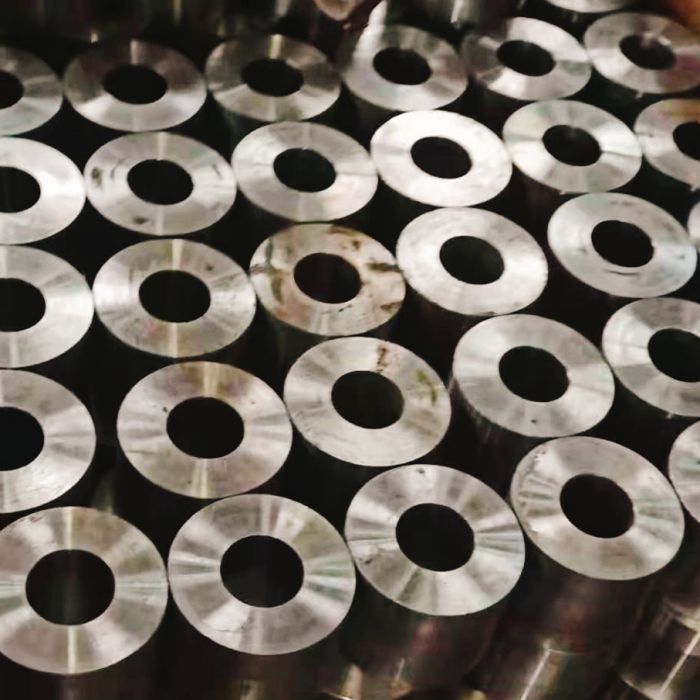

1.2436 turned rounds

1.2436 high wear-resistant chromium steel, high carbon, high chromium ledeburite steel, cold work die steel.. Used to make cold work die with large cross-section, complex shape, high impact force and high wear resistance. Cold work molds include cold punching dies, wire drawing dies, drawing dies, stamping dies, thread rolling dies, thread rolling plates, cold heading dies and cold extrusion dies. The cold work die is made of steel, which should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability, hardenability and other process properties according to the working conditions of its manufacture. Alloy tool steels used for this kind of purposes generally belong to high-carbon alloy steels, with a carbon mass fraction above 0.80%. Chromium is an important alloying element of this type of steel, and its mass fraction is usually not more than 5%. However, for some steels with high wear resistance and small deformation after quenching, the highest chromium mass fraction can reach 13%, and in order to form a large amount of carbides, the carbon mass fraction in the steel is also very high, up to 2.0%~ 2.3%. Cold work die steel has a high carbon content, and most of its structure is hypereutectoid steel or ledeburite steel. Commonly used steels include high carbon low alloy steel, high carbon high chromium steel, chromium molybdenum steel, medium carbon chromium tungsten steel, etc.

Email Details -

1.2363 cold work tool steel

A2 steel is an air-quenched die steel with deep air-quenched hardening properties, which is extremely beneficial for complex molds that must maintain their shape after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. The wear resistance is between manganese and high-carbon and high-chromium tool steels. Its toughness is better than any one, especially It is suitable for tools that require good wear resistance and special toughness. It is widely used in blanking dies and forming dies, rolls, punches, calendering dies and thread rolling dies, and also used in some types of scissors blades. . Cold work die steel is A2 steel imported from the United States, and it is the most widely used type of A-type air-quenched steel. It is suitable for cold work die steel that requires both wear resistance and toughness. It can replace CrWMn and 9Mn2V steel to make medium and small cold blanking dies, blanking dies, forming dies and punches.

Email Details -

1.2842 blade steel

1.2842 steel is cold work die steel is easy to forge and requires a hardness of 63HRC.

Email Details

chemical composition

1.2842 chemical composition (mass fraction): C0.85% ~0.95%, Si0.10% ~0.40%, Mn1.90%~2.10%, P≤0.030%, S≤0.030%, Cr0.20% -0.50% , V0.05% ~0.15%.

Reference corresponding grade

Chinese GB standard grade 9Mn2V, international standard ISO grade 90MnV2, German DIN standard grade 90MnV8, German DIN standard material number 1.2842, American ASTM standard grade 02, British BS standard grade B02, Sweden ASSAB (ASSAB) standard grade DF- 20 -

1.2550 STEEL

1.2550 steel is a steel grade formed by adding a certain amount of tungsten on the basis of chromium silicon steel, because tungsten helps to preserve the finer grains during quenching, and obtains higher toughness in the tempered state.

Email Details -

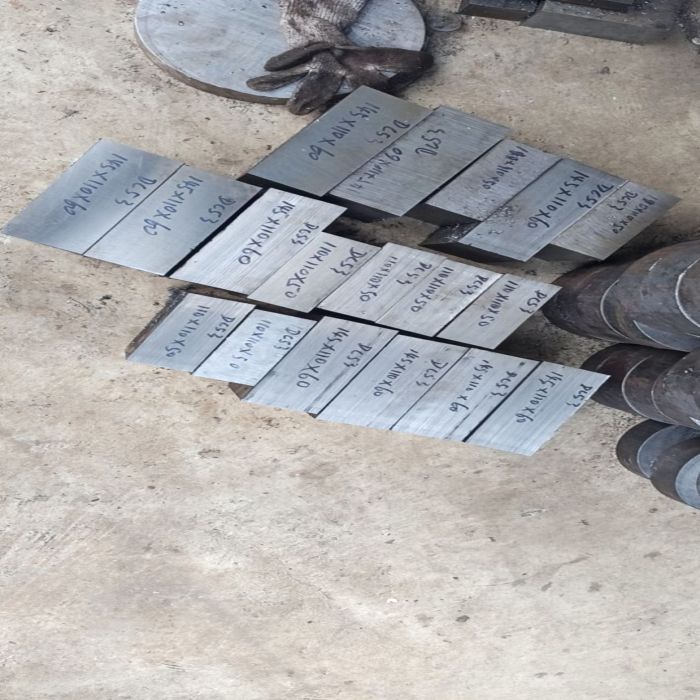

SKD11 bright finish

SKD11 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure and has good hardenability and small quenching deformation.

Email Details